Product alias:

Tube rolling machine,tube grooving machine, tube shrinking machine, tube groove wheel machine, wheel convex machine, pipe cutting machine, wheel cutting machine,conveyor grooving machine,inner grooving machine, slotting machine

Scope of application :

Tube or pipe assembly products can be a complete or not complete tube rolling grooving and cutting . Its used in the industrial of conveyor, baby stroller, kids tricycle, baby playpen, bicycle, motorbike, automobile, exercise equipment,buffer, deck chair, chaise lounge, furniture, house wares, sanitary wares, recreational facilities, rehabilitation and medical instruments, stainless chopsticks,…etc.

Feature of product:

- ※High quality tube grooving on demand with no roller marks.

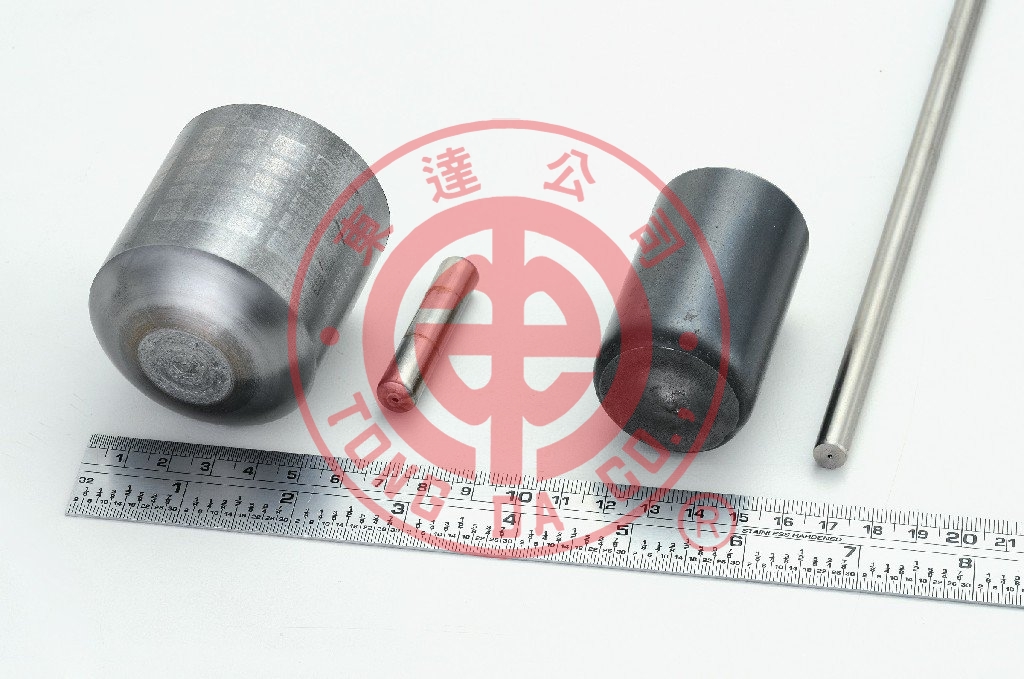

- ※Variety of metal materials (Steel, stainless steel, copper, aluminum, etc) are adaptable to grooving round tube.

- ※Hydraulic design permits an accurate and steady performance in connection with the groove depth or projection height.

- ※ The special design of the advance and retreat groove mechanism can greatly shorten the processing time of the advance and retreat pipe.

- ※ It is easy to change the groove blade and the groove axis.

- ※Easily-operated, even by an unprofessional person.

- ※ The model is small and beautiful, the chassis is stable and does not take up space.

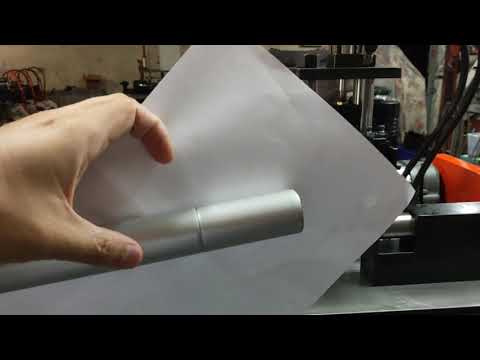

* Speed thin/thick tube cutting.

* Adaptable to cutting round tube of various materials including steel, stainless steel, copper, aluminum, etc.

* Connection with a non-skid rolling assistant cup permits the cutting to be easier, faster and neat. No iron scraps and no wastes.

* Whenever bearing bracket moving up and down, cutter blade always stays at a fixed supporting point between special steel wheels so as to make full use of its highest performance and accuracy.

* Easily-operated, even by an unprofessional person. Cutter blade can be sharpened by client himself to keep cost down.

* Compact design, nice looking, stable base and space-saving.

Models | TD-41335 | TD-41350 |

Outer diameter of tube | 13 ~ 35mm | 13 ~ 50mm |

Thickness of tube | 0.5mm ~ 1.6mm | 0.5mm ~ 2.0mm |

Length of tube | unlimited | unlimited |

Speed of grooving tube | More than 3 seconds, according to tube diam. and thickness | More than 3 seconds, according to tube diam. and thickness |

Horsepower | 2 HP | 3 HP |

Total length | 700 mm | 750 mm |

Total width | 450 mm | 500 mm |

Total height | 1450 mm | 1500 mm |

Net weight | 195 kg | 230 kg |

Gross weight | 235 kg | 265 kg |

※In the event of any changes of above, specification of the real machine shall prevail.

Speed thin/thick tube cutting.

* Adaptable to cutting round tube of various materials including steel, stainless steel, copper, aluminum, etc.

* Connection with a non-skid rolling assistant cup permits the cutting to be easier, faster and neat. No iron scraps and no wastes.

* Whenever bearing bracket moving up and down, cutter blade always stays at a fixed supporting point between special steel wheels so as to make full use of its highest performance and accuracy.

* Easily-operated, even by an unprofessional person. Cutter blade can be sharpened by client himself to keep cost down.

* Compact design, nice looking, stable base and space-saving.